- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Technology Spotlight: Shrink-fit machines plug in

New series is network-compatible with scanner options

- By Sue Roberts

- June 11, 2018

- Article

- Cutting Tools

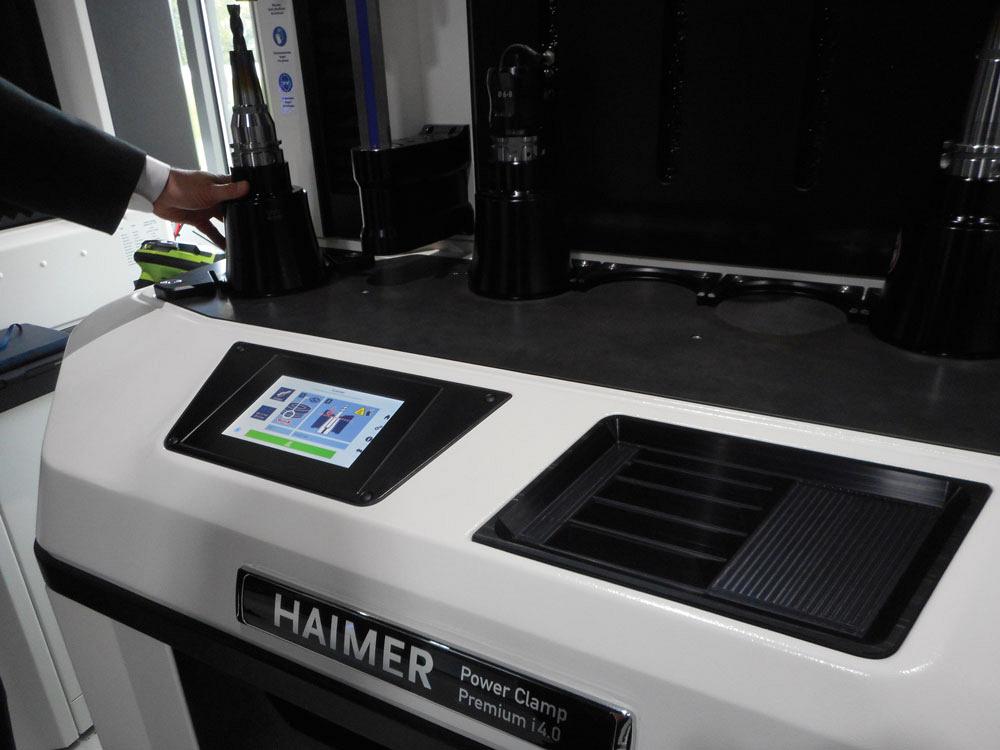

Craig Schepers, regional sales manager whose territory includes Winnipeg and Manitoba, demonstrated how the scanner communicates with the Power Clamp Premium i4.0 during a recent Haimer USA open house in Villa Park, Ill.

A new series of Haimer shrink-fit machines have joined the shop floor data conversation. The new, automated Power Clamp i4.0 series is interface-enabled for data communication with a company’s production network. The three models, the Power Clamp Premium i4.0, Sprint i4.0, and Comfort i4.0, can also be equipped with a scanner to read the shrinking parameters from data matrix codes.

The shrink-fit system works with the company’s toolholders that have a dot matrix bar code identification system. Communications determine where the intelligent NG coil system should be positioned to heat the chuck only where needed. It takes four to five seconds to heat the toolholder to approximately 350 C. Then the system automatically signals the right cooling station in a multiple-station system and cooling is completed in about 30 seconds.

A 7-in. colour touchscreen display and new software are incorporated into the i4.0 series machines for easy and intuitive operation. Illustrated functions and symbols guide operators through the steps needed to achieve a secure grip on solid-carbide and high-strength steel tools with diameters from 3 to 32 mm.

“This technology is for manufacturers who want to grow for the future and be able to compete,” said Steven Baier, Haimer national sales manager. “The ability to post-process through the machine and use RIFD to get that information into the machine tool with the least possibility for an error will make a company much more productive.”

The Power Clamp Sprint i4.0 incorporates a new cooling system that uses air and a spray mist to cool shrink-fit chucks and collets regardless of the tool geometry. An optional length presetter can be added to this model.The Power Clamp Premium i4.0 features an automated, integrated cooling position indicator for its five contact cooling stations. The Power Clamp Comfort i4.0 also has an integrated contact cooling control system with a three-station rotary table and an optional upgrade for heavy-duty shrink chucks.

Baier said that the i4.0 series of shrink-fit machines, particularly when added to other connected technologies like presetting, measuring, balancing, tooling, and tool management, can be part of a complete system that contributes to faster setup times, improved machine utilization, reduced scrap, and improved tool life.

Associate Editor Sue Roberts can be reached at sroberts@canadianmetalworking.com.

Haimer USA LLC, 630-833-1500, www.haimer-usa.com

About the Author

Sue Roberts

2135 Point Blvd

Elgin, IL 60123

815-227-8241

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

Roberts is a Northern Illinois University journalism graduate.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI